Lean Manufacturing: The top approach to process improvement for shops

Published

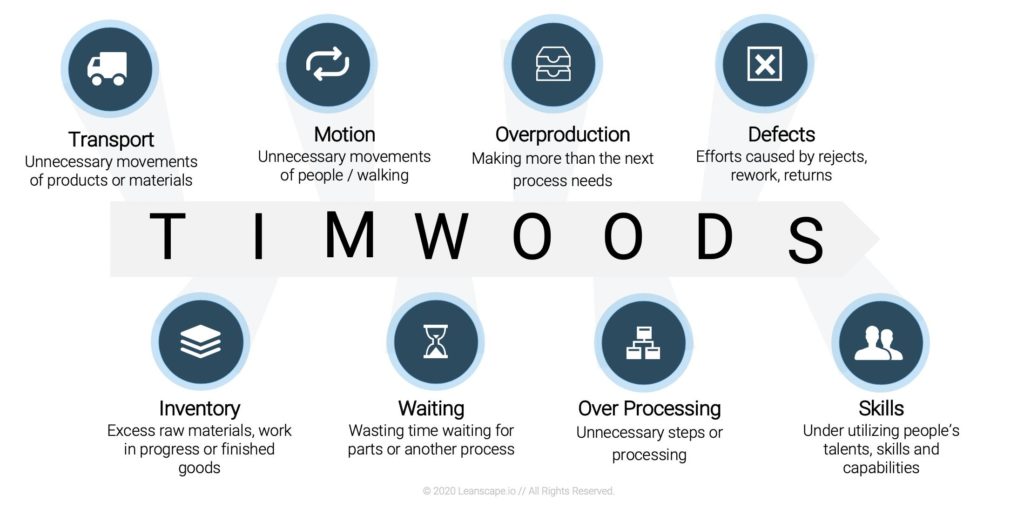

Photo courtesy of Leanscape

Your shop’s operations are really just a collection of processes, designed to get a customer from initial lead to completed sale, and designed to get their car from dropped off with an agreed job to picked up with a completed job.

Simplifying your shop to this basic foundation makes it really easy to begin optimizing your processes. There is always room to be more efficient, deliver higher quality work, and create a better customer experience.

In today’s DPA Weekly, I want to share an approach to identifying opportunities for process improvement, taken from Lean Manufacturing. That approach is called TIM WOODS.

TIM WOODS is an acronym identifying eight different sources of waste in a process. In the spirit of Lean, I am going to jump right into explaining them by providing examples of areas in which you can look for process improvement opportunities.

Transportation

How much time and energy do you spend moving a car around? Do you have to move it between multiple facilities or workstations? How about new parts? Do you have multiple parts staging areas?

Inventory

Do you have an unfinished shop car (a form of marketing inventory) buried in the back corner? Do you have more cars in the shop than can possibly be worked on at any given time?

(excess) Motion

How much time do your employees spend walking to their toolbox or the garbage can? How much time do you spend walking between employees and back to your office?

Waiting

How often does a car sit in your shop waiting for parts? Whether or not you give deadlines to a customer or just keep them internally, how often are they missed? Do you have to reschedule the drop off for the next project because of your missed deadline – now your customer is waiting too.

Overprocessing

Do you ever spend so much time doing a task on a car that it feels overdone? It’s one thing to be a perfectionist, it’s another to focus on 100% when the customer will accept 99.9%. The law of diminishing returns says that the last 0.1% will be the hardest to achieve and take the most time.

Overproduction

Do you buy parts and materials “just in time,” or do you stockpile? Do some of your stockpiles collect dust when they are under sold?

Defects

How often do you have to redo or warranty your mistakes? Defects are the most common and easily visible form of waste for shops.

Skills

Do you have team members who are underutilized? Do you have your top fabrication tech doing bolt-on installs, or the bumper wrapping expert doing a simple quarter panel?

Lean Manufacturing and its accompanying principles, such as Kaizen, emphasize continuous improvement. In the examples listed above, there are tons of impossible standards and “unreasonable” expectations. However, as you raise your standards of production and continuously optimize your processes, you’ll eventually find that what was once unreasonable is now attainable.

I worked with a shop where cars would sit for weeks at a time, waiting for parts or waiting for the time to be worked on. They would end up extremely dusty and potentially even lightly damaged from sitting in the busy shop for so long. While there was tons of waste and opportunities for improvement as far as the eye could see, we broke it down into chunks. An immediate problem we could solve was delivering cars back to customers dusty after sitting for so long. The dust would really take away from the excitement of picking up their completed car.

As a temporary solution, the shop bought a pressure washer and began washing every car on the day of pickup. This drastically improved customer satisfaction and forced the shop to look at optimizing its job processing. As an obviously wasteful short-term solution, the shop pushed hard to optimize their job processing efficiency, and after two months, they were able to stop washing cars – nothing sat long enough to need it.

In conclusion

TIM WOODS gives you a detailed perspective for identifying waste and opportunities for process improvement. What may seem like a mountain to climb becomes much more simple when broken down into components and prioritized to solve problems and adopt a mindset of continuous improvement.

Driven Performance Advisors

Driven Performance Advisors helps shop owners and specialty parts companies increase efficiency and improve profitability to grow to $5M in sales. Schedule a consultation at drivenperformanceadvisors.com. Subscribe to DPA Weekly at drivenperformanceadvisors.com/dpa-weekly/.